What is LVL Furniture Moulding?

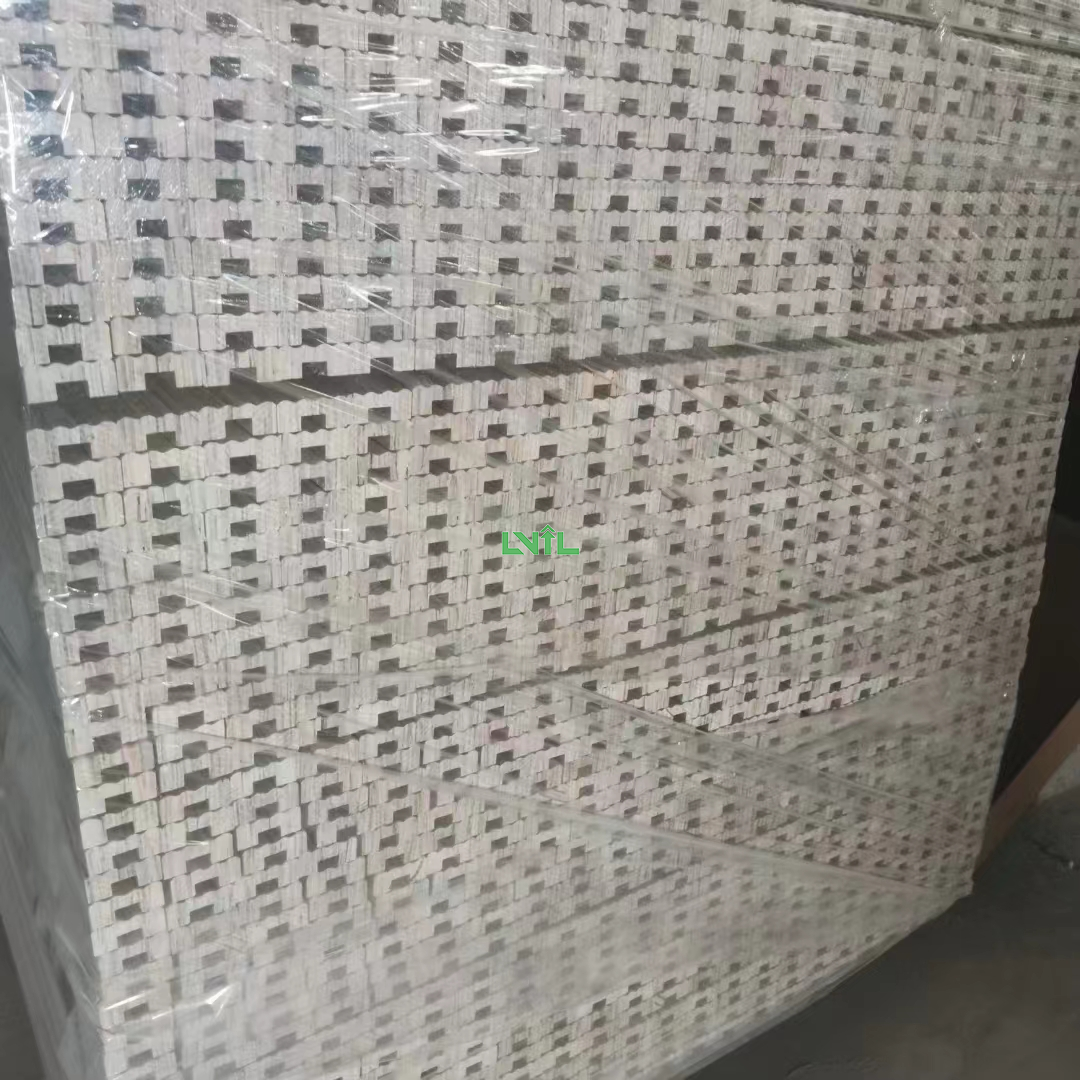

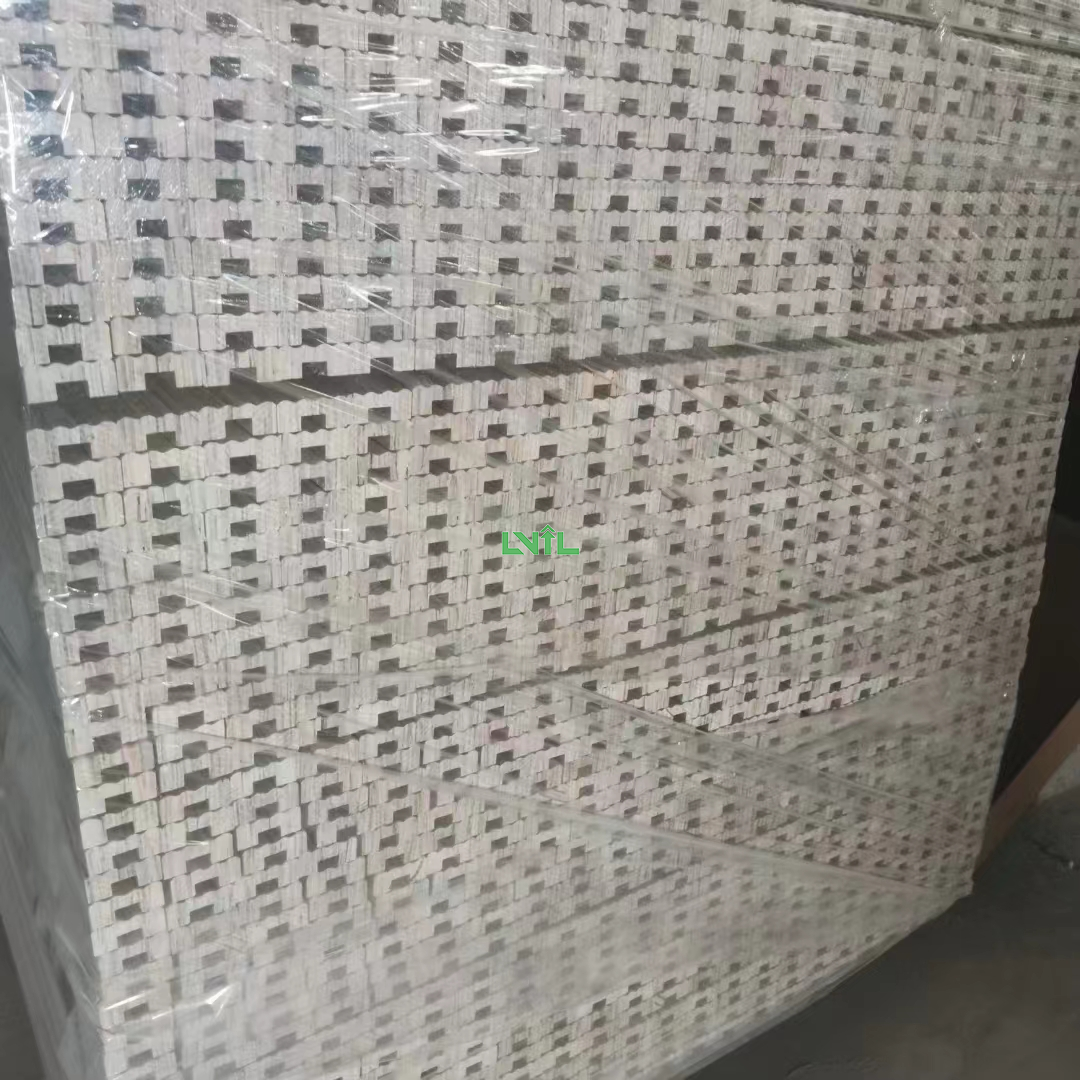

LVL (Laminated Veneer Lumber) furniture moulding is an engineered wood product created by bonding multiple layers of thin wood veneers together under heat and pressure, with each layer oriented in the same direction for added strength and durability. LVL is known for its excellent dimensional stability, resistance to warping, and high strength-to-weight ratio, making it ideal for furniture moulding applications. LVL furniture moulding is widely used for frames, decorative trims, and structural support in various types of furniture.

www.uniquenewmaterial.com

山东优科新材料有限公司

山东优科新材料有限公司

Powered by Unique

Production of LVL Furniture Moulding

The production of LVL furniture moulding involves several key steps to ensure the finished product is robust, dimensionally stable, and ready for use in furniture manufacturing: 山东优科新材料有限公司

- Wood Veneer Selection and PreparationThe process begins with selecting high-quality veneers, which are thin sheets of wood. Common species used for LVL include fast-growing, renewable woods like pine, poplar, or other hardwoods, depending on the final appearance and strength requirements.

- Drying and SortingAfter selection, the veneers are thoroughly dried to reduce moisture content, which is crucial for producing stable, warp-resistant LVL. They are then sorted and graded to ensure uniform quality.

- Application of AdhesiveAn adhesive, usually a high-quality, eco-friendly resin, is applied between each layer. The adhesive not only binds the layers together but also enhances the structural integrity of the LVL, ensuring it can withstand high stress and load.

- Layering and PressingThe veneers are carefully stacked with the grain running in the same direction, which creates a unidirectional grain structure that contributes to the strength of LVL. This layered assembly is then subjected to heat and pressure in a large press. The pressure ensures a uniform bond between the layers, creating a single, solid piece of LVL.

- Cutting and ShapingAfter pressing, the LVL is cut and machined into the desired shapes and dimensions for furniture moulding applications. This stage allows for customization, enabling manufacturers to create precise profiles and dimensions according to specific furniture designs.

- FinishingIn the final step, LVL moulding may undergo additional finishing processes, such as sanding, coating, or veneering, to give it an attractive, finished look that complements various furniture styles.

Powered by Unique

Powered by Unique

Applications of LVL Furniture Moulding

LVL furniture moulding offers a range of applications in the furniture industry due to its strength, versatility, and aesthetic potential. Here are some of its primary uses:

www.uniquenewmaterial.com

- Furniture FramesLVL is commonly used in the construction of furniture frames for sofas, chairs, and beds, providing a strong and lightweight structural framework. Its ability to hold nails and screws securely makes it ideal for load-bearing parts of furniture.

- Decorative Moulding and TrimsLVL is well-suited for creating decorative mouldings, trims, and edging in furniture, such as around cabinet doors, tabletops, and shelves. LVL mouldings can be designed in various shapes and profiles, adding a stylish, finished look to furniture pieces.

- Doors and PanelsLVL furniture moulding can also be used to create stable, warp-resistant door and panel structures in cabinets, wardrobes, and other storage units. Its consistent grain and strength make it a reliable material for panels that are both functional and aesthetically appealing.

- Architectural Furniture ElementsLVL is sometimes used for unique architectural furniture elements, such as in modern shelving units, room dividers, and wall panels. Its strength allows it to support significant weight, while its smooth finish allows it to integrate seamlessly into contemporary furniture designs.

Copyright Unique

Advantages of Using LVL in Furniture Moulding

- Strength and DurabilityLVL is exceptionally strong and less prone to splitting, shrinking, or warping compared to solid wood. This makes it highly durable, which is especially important for furniture that endures heavy use or weight.

- Dimensional StabilityThe layered structure of LVL ensures it remains dimensionally stable, even in fluctuating temperature and humidity conditions. This stability makes it ideal for furniture pieces that need to retain their shape and strength over time.

- Efficient Use of ResourcesBy using thin veneers and maximizing wood usage, LVL is considered an efficient and environmentally friendly choice. It reduces wood waste, supports sustainable forestry practices, and utilizes fast-growing wood species, making it a more responsible choice for manufacturers and consumers.

- Cost-Effective AlternativeLVL is generally more affordable than solid hardwood, offering a cost-effective alternative for furniture makers without compromising on performance or aesthetics.

In conclusion, LVL furniture moulding combines the best features of engineered wood, providing manufacturers and designers with a versatile, strong, and sustainable material. Its unique properties make it suitable for a wide range of furniture applications, from structural frames to decorative trims, offering a modern solution that balances quality, cost, and environmental responsibility. 山东优科新材料有限公司

山东优科新材料有限公司

山东优科新材料有限公司  Powered by Unique

Powered by Unique